INJECTION TOOLING.

- Suase /

- Composite Tooling /

- INJECTION TOOLING

What is Plastic Injection Molding?

Plastic injection molding, or commonly referred to as injection molding, is a manufacturing process used in the mass fabrication of plastic parts. It involves an injection of molten plastic material into the mold where it cools and solidifies to its final form. It is ideal for manufacturing high volumes of plastic products, which serves many industries and individuals.

The mold is customized during tooling which gives the shape of the part. It can create numerous parts that are identical and dimensionally consistent, even on parts with complex designs and parts that only allow low dimensional tolerance.

Advantages of Plastic Injection Molding

High productivity

The injection molding process is a quick method of forming plastic parts. It has a fast production rate and is capable of producing voluminous plastic parts in a single cycle. The mold may contain multiple cavities. The more cavities are contained in the mold, the more parts it can produce in a single molding cycle. Also, it can produce thousands of parts before the tooling needs to be maintained.

Highly repeatable

Injection molding can produce multiple parts with consistent form and dimensions. The parts produced in different molding cycles are guaranteed to be identical. This advantage is necessary when product consistency is required.

Low scrap rates

Injection molding generates less scrap compared to traditional manufacturing processes and CNC machining. Excess plastics coming from the sprue, runners, and gates after the injection molding process may be heated and remolded if a recyclable thermoplastic material is used.

Low labor costs

Injection molding is a highly automated process where most of its steps are performed by the machine controlled by an operator and intervention by manual labor is minimal. This reduces the manufacturing cost.

Disadvantages of Plastic Injection Molding

Expensive tooling

The mold tooling is designed, fabricated, and tested before mass production, which increases the investment cost. Before a conceived design is produced by injection molding, a prototype mold tool is designed and produced to mold the first parts of the new design. Several iterations and trial runs must be done to ensure that the mold produces a part with accurate dimensions, which can be very expensive and time-consuming.

Difficult to make changes in the part design

Any change in the form and dimensions of the part requires modifications in the dimensions of the mold cavities. If the size of the part is to be increased, a portion of the cavity must be stripped away so that the molten plastic can occupy a larger volume. Since the tooling is made up of hard metal, metal fabrication methods must be used. If the size of the part is to be decreased, a new tool with smaller cavities is required.

Limitations in the part design

The part design, as much as possible, must have:

· A uniform wall thickness to allow uniform cooling and to avoid shrinkage and other defects.

· A low wall thickness and volume, to achieve a uniform and shorter cooling time since a small amount of hot plastic is allowed to cool. As a rule of thumb, the wall thickness of the part should be kept at a minimum of 6 mm.

· Reduced external or internal undercuts. This is to minimize tooling costs.

Process of Plastic Injection Molding

Plastic injection molding is a manufacturing process where resin in a barrel is heated to a molten state, then shot into a mold to form a part in the shape of the mold. The resin begins as plastic pellets, which are gravity fed into the injection molding machine through a funnel-shaped hopper. The pellets are fed from the hopper into a heated chamber called the barrel where they are melted, compressed, and injected into the mold’s runner system by a reciprocating screw.

As the granules are slowly moved forward by a screw-type plunger, the melted plastic is forced through a nozzle that seats against the mold sprue bushing, allowing it to enter the mold cavity through a gate and runner system. The injection molded part remains at a set temperature so the plastic can solidify almost as soon as the mold is filled.

The part cools and hardens to the shape of the mold cavity. Then the two halves of the mold (cavity or “A” side and core or “B” side) open up and ejector pins push the part out of the mold where it falls into a bin. Then the mold halves close back together and the process begins again for the next part.

Raw Materials used in Plastic Injection Molding

There are many plastic or resin materials available in the manufacturing industry. Selecting the right match for your custom injection molding project is essential to producing a high-quality part. Each material will have its own set of unique characteristics and chemical makeup. When selecting the best material for your injection molding project, consider the durability, performance, texture, flexibility, density and color.

For example: PC/PP/PVC /PMMA/ABS/PS/LDPE/POM/HIPS etc.

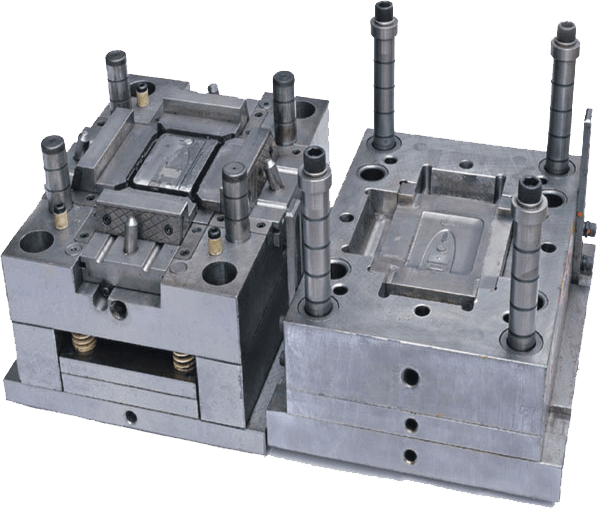

Plastic Injection Molds

Injection molds, or mold tooling, are the formed halves that come together in the injection molding machine to be filled with molten plastic and produce the plastic parts in their image. The cavity side, or “A” side, is typically the half which will form the “best” surface of the part, and the core side, or “B” side, will typically show the visual imperfections caused by ejector pins because the parts get ejected from this half.

Injection molds are manufactured by machining or by Electrical Discharge Machining (EDM). Standard machining was the traditional method of building injection molds with a knee mill. Technology advanced the process, and Computer Numerical Control (CNC) machining became the predominant method of making complex molds, with more accurate details, and in less time than the traditional method.

EDM is a process in which a shaped, copper or graphite electrode is slowly lowered onto the mold surface, which is immersed in paraffin oil. Electric voltage applied between the tool and the mold causes spark erosion of the mold surface in the inverse shape of the electrode. EDM has become widely used in mold making – many injection mold companies now have EDM in-house. The process allows the formation of molds which are difficult to machine, such as those with features such as ribs or square corners. It allows pre-hardened steel molds to be shaped without requiring heat treatment.

Compared to other plastic manufacturing processes such as CNC machining or 3D printing, injection molding has a high up-front investment because the tooling is expensive. However, for large production runs of thousands or even millions of identical parts, injection molding is typically less expensive in the long run, despite the high initial tooling investment, because of a lower piece price at high volumes. In addition, it is a much faster manufacturing process than the others mentioned.

Molds can be made of pre-hardened steel, steel that is hardened after the mold is produced, aluminum, and/or beryllium-copper alloy. The choice of mold material is determined in part by the number of parts to be produced.

Steel molds will generally have a longer lifespan, so a higher initial cost will be offset by longevity – it will be capable of producing a higher number of parts before wearing out. Pre-hardened steel injection molds are less wear-resistant than those hardened by heat treatments after they are machined, so they are used for lower volume part requirements.

Depending on varying economic conditions and material origin, aluminum molds can in some cases cost substantially less than steel molds. Aluminum molds have a quick build time, and can produce faster cycle times because of better heat dissipation than steel. Beryllium copper can also be used in areas of the injection molds that require fast heat removal, or in areas where the most shear heat is generated.

Additional complexity can be added to injection molds in order to produce more complex plastic parts. In the basic process of injection molding, the two mold halves separate at the end of the molding cycle and the part is ejected. In this simple case, the part design cannot have any overhanging or undercut part features, because the mold halves would catch on each other when pulling apart.

So, to accommodate part features such as undercuts, molds can be augmented with side-pull mechanisms called slides. Slides move into a cavity in a perpendicular direction from the draw of the mold halves to form the undercut feature, then stationary angle pins on the stationary mold half pull the slides away when the mold is opened. The pins enter a slot in the slides, and cause them to move backward when the moving half of the mold opens, like a cam. Then the part is ejected, the mold closes, and the slides move forward along the angle pins as a result of the closing action of the mold.