Introduction

The evolution of battery technology, particularly in electric vehicles (EVs) and energy storage systems, has underscored the importance of thermal management to enhance safety and performance. One of the most critical advancements in this domain is the development of composite battery cases, which incorporate innovative designs for managing thermal runaway. This article delves into the thermal runaway management strategies, flame impact performance testing, and the innovative cooling piping systems utilized in these composite battery cases.

Thermal Runaway Management

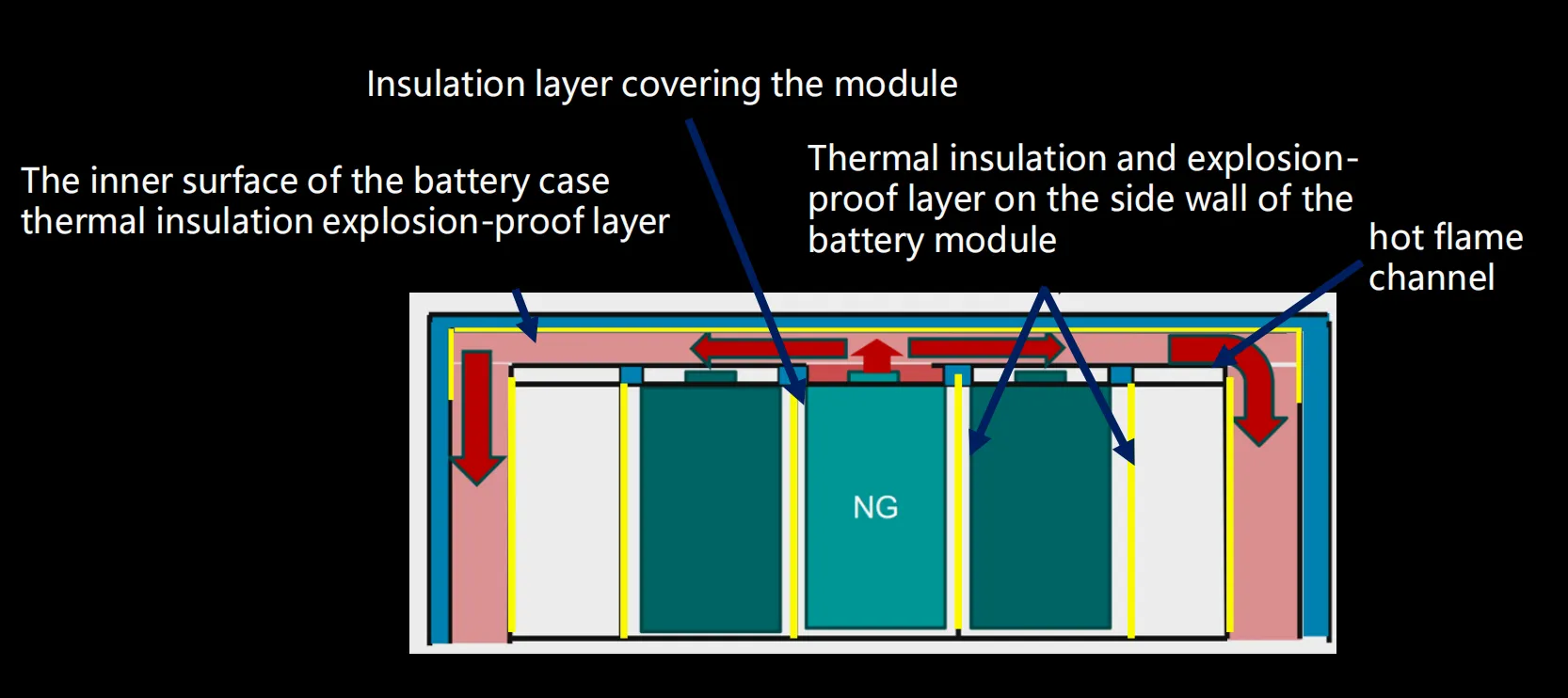

Thermal runaway is a significant concern for lithium-ion batteries, where an increase in temperature can lead to a self-sustaining reaction, potentially resulting in fire or explosion. To mitigate this risk, the composite battery case features a unique flame channel design.

Flame Channel Design

- Controlling Flame Path: By directing the path of the flame, the channel helps guide it away from the battery cells, minimizing the risk of ignition of adjacent cells.

- Pressure Relief: The design allows for pressure relief during thermal events, reducing the likelihood of catastrophic failure.

- Flame Containment: The flame channel prevents the spread of flames beyond the battery case, enhancing overall safety.

Sample Fire Tests

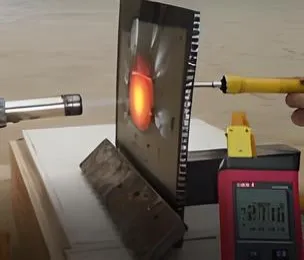

To validate the effectiveness of the thermal management design, a series of fire impact performance tests were conducted on the composite battery case. These tests aimed to assess the case's ability to withstand extreme temperatures and prolonged exposure to flames.

Test 1: High-Temperature Exposure

Conditions: The sample was subjected to a flame temperature of 1300 degrees Celsius for 30 minutes.

Results: The surface of the sample showed no visible flames, no burn-through, and no structural collapse. The case maintained its rigidity, demonstrating excellent thermal resistance.

Test 2: Moderate-Temperature Exposure

Conditions: The sample faced a flame temperature of 600 degrees Celsius for 30 minutes.

Results: Again, there were no flames on the surface, no burn-through, and the temperature on the reverse side remained around 130 degrees Celsius. This indicates effective heat insulation and resistance.

Compliance with National Standards

These tests confirm that the composite battery case meets the requirements of the new national standard GB38031-2020, which mandates that flames must not spread outside the battery case within five minutes of exposure.

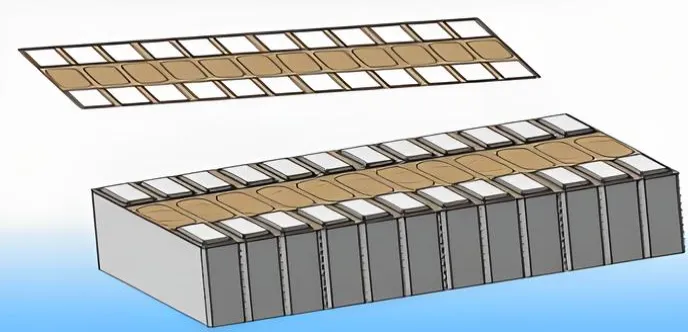

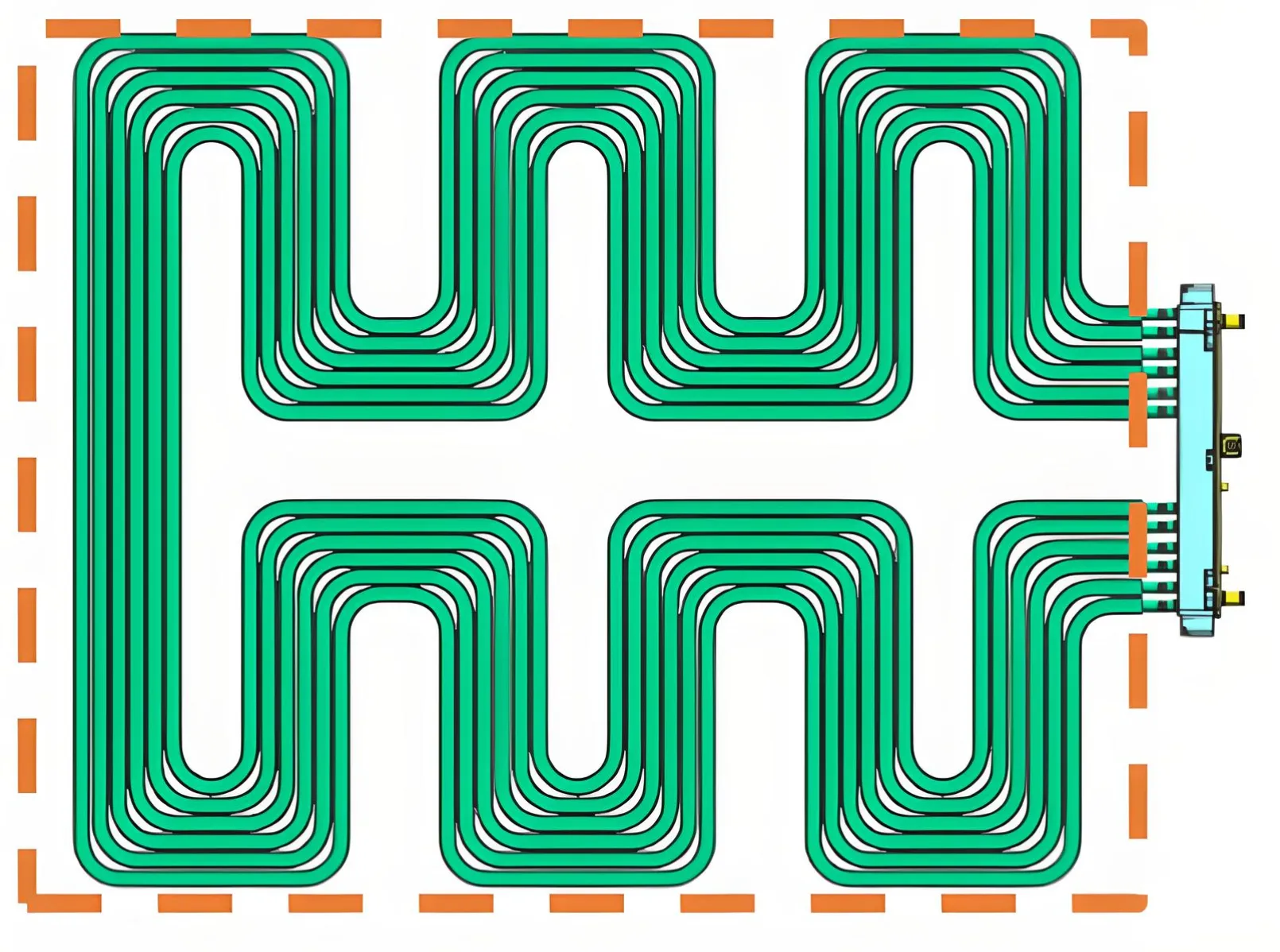

Innovative Cooling Piping System

In addition to flame management, effective cooling is vital for maintaining battery performance and longevity. The innovative cooling piping system integrated into the composite battery case is designed to achieve optimal heat distribution.

Design Features

- Parallel S-shaped Pipelines: The cooling circulation system employs multiple sets of parallel S-shaped pipelines. Each pipeline is of equal length, ensuring uniform flow velocity across the system.

- Heat Exchange Mechanism: The alternate flow direction of coolant between the pipes facilitates efficient heat exchange, promoting thermal equilibrium within the battery case.

- Seamless Pipeline Construction: The cooling pipes are designed without joints, minimizing the risk of coolant leakage due to aging seals or welding defects. This seamless design enhances reliability and safety.

- Cost-Effective Solution: The use of traditional piping materials offers a more economical alternative to harmonica pipes, making the system not only efficient but also cost-effective.

Conclusion

The development of composite battery cases represents a significant advancement in thermal management technology for lithium-ion batteries. By integrating innovative flame management systems and a robust cooling piping network, manufacturers can enhance the safety, reliability, and performance of battery systems. As the demand for electric vehicles and renewable energy storage solutions continues to grow, these technologies will play a pivotal role in ensuring the safe and efficient operation of battery-powered systems.

For manufacturers and consumers alike, investing in advanced thermal management solutions is not just a matter of compliance, but a commitment to safety and performance in an ever-evolving technological landscape.