Advantages of PP+SMC Composites for Automotive Front Covers and Rear Tailgates

- Suase /

- SUASE NEWS

1. Weight Reduction: A Key Advantage in Vehicle Efficiency

One of the most compelling reasons for using PP+SMC composites in automotive components is the significant weight reduction they offer. Compared to traditional materials like sheet metal and aluminum:

- 25-40% lighter than sheet metal - This reduction in weight improves fuel efficiency and reduces emissions.

- 10-25% lighter than aluminum - PP+SMC composites offer further weight reduction compared to aluminum, enhancing vehicle performance.

Overall, weight savings from PP+SMC make it easier for automakers to meet fuel efficiency and sustainability goals.

2. Enhanced Noise Cancellation for a Quieter Ride

In addition to weight reduction, PP+SMC composites provide superior noise, vibration, and harshness (NVH) control, creating a quieter cabin environment.

- Vibration damping properties - PP+SMC composites reduce road noise and engine vibrations effectively.

- Improved acoustic performance - These composites offer a barrier against exterior noise, enhancing passenger comfort.

3. Cost-Effectiveness and Lower Development Costs

PP+SMC composites also stand out for their cost-effectiveness, particularly in terms of development and production.

- Reduced tooling and manufacturing costs - PP+SMC components need less expensive tooling compared to metals, reducing production costs.

- Streamlined production process - These composites can be molded into complex shapes with minimal post-processing, which speeds up production and reduces labor costs.

4. Flexible Design Freedom for Customization

PP+SMC composites provide design flexibility that enables automotive engineers to innovate with ease.

- Complex geometries - PP+SMC can be molded into intricate forms, supporting creative design approaches.

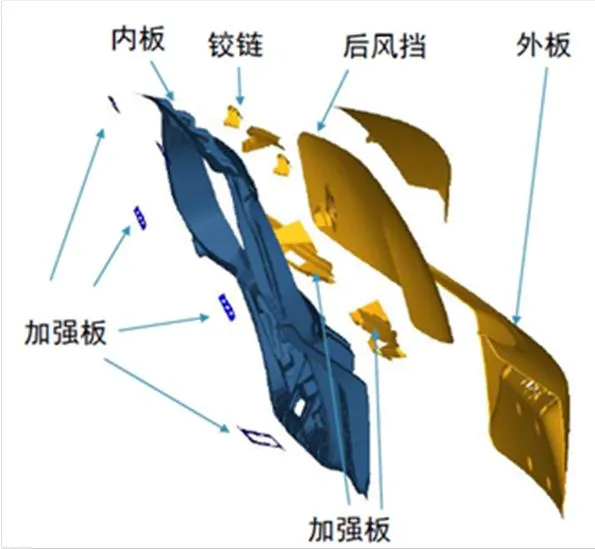

- Integrated features - Various structural and functional elements, such as ribs and mounting points, can be integrated directly into the part.

- Aesthetic finishes - PP+SMC components can be produced with different surface finishes, enhancing vehicle aesthetics.

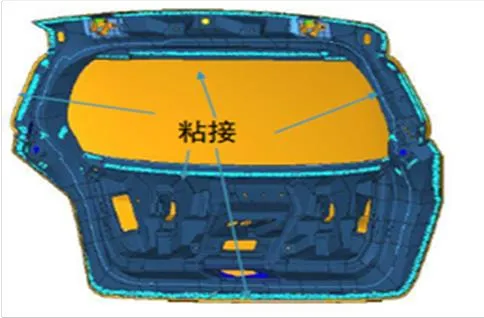

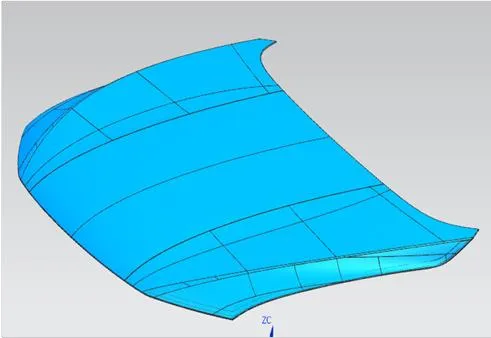

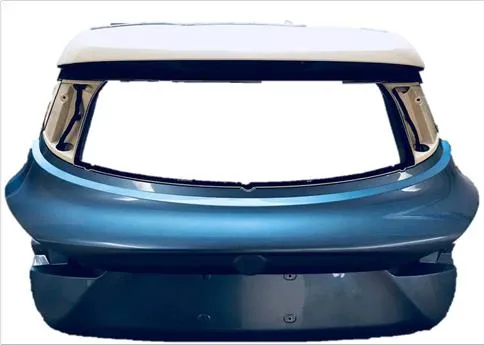

PP+SMC Applications: Front Covers and Rear Tailgates

PP+SMC composites are particularly well-suited for full plastic front covers and rear tailgates in vehicles, thanks to their durability, impact resistance, and weather resilience. Key benefits include:

- Durability and impact resistance - PP+SMC composites withstand minor impacts without denting, unlike metal parts.

- Weather resistance - PP+SMC is naturally resistant to moisture, UV rays, and chemicals, extending part lifespan.

- Enhanced safety - PP+SMC absorbs impact energy, which can improve safety in case of collisions.

Conclusion: Why PP+SMC is the Future of Automotive Components

PP+SMC composites are a breakthrough in material innovation, providing lightweight, durable, and cost-effective solutions for automotive applications. With benefits in weight reduction, noise cancellation, cost-efficiency, and design flexibility, PP+SMC is becoming the top choice for components like front covers and rear tailgates. As automakers continue focusing on efficiency and sustainability, PP+SMC composites are set to play a central role in the future of vehicle design and production.