Compression Molding

Compression molding involves placing prepared sheets of carbon fiber into a heated mold, applying pressure, and curing them into strong components.

Explore the possibilities of molding carbon fiber and its applications across industries.

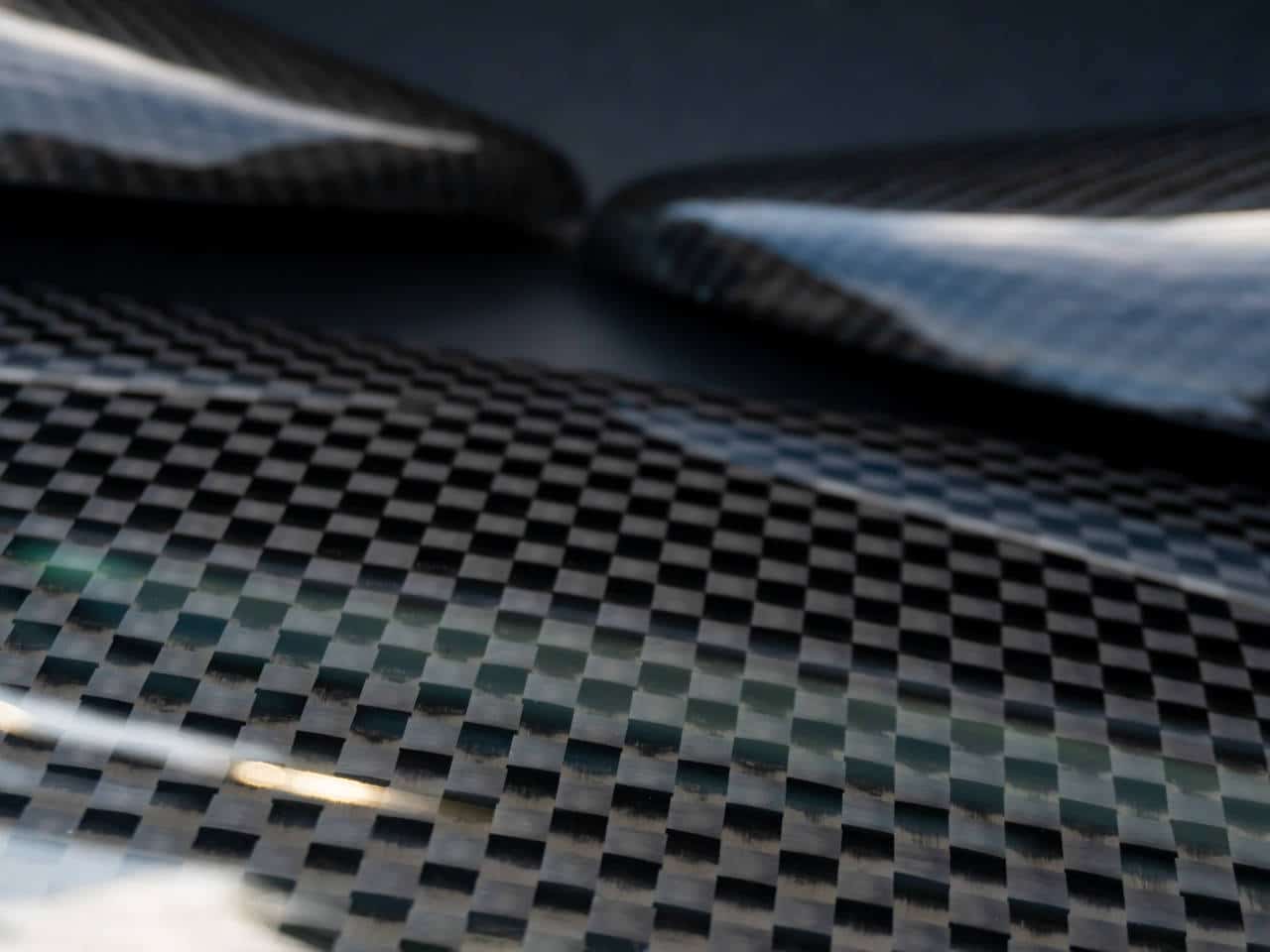

Carbon fiber is a lightweight, high-strength material known for its remarkable properties, including high tensile strength, corrosion resistance, and design flexibility. These characteristics make it ideal for manufacturing components requiring precision and durability.

The answer is yes. It can be shaped into complex forms using special techniques. Unlike thermoplastics, carbon fiber composites need to be heated to take the final shape. This is typically done by combining woven carbon fiber sheets with epoxy resin.

Compression molding involves placing prepared sheets of carbon fiber into a heated mold, applying pressure, and curing them into strong components.

In vacuum bagging, carbon fiber layers are sealed in a vacuum bag, which is then evacuated of air, and cured. This process ensures high-quality finishes and strength.

This process injects liquid resin into a closed mold containing carbon fiber, creating strong and durable parts for structural applications.

In filament winding, strands of carbon fiber are wound onto a rotating mandrel, which is ideal for making cylindrical shapes like pipes and pressure vessels.

In hand lay-up, workers manually layer carbon fiber sheets on a mold. Then they soak the sheets in resin. This process is often used to make custom or prototype parts.

Molded carbon fiber is extensively used in:

While it has many advantages, carbon fiber molding is challenging. It costs a lot, it needs special equipment, and it is a very labor-intensive process.

Innovations like automated lay-up systems, advanced resins, and 3D carbon fiber printing are making carbon fiber molding better. These advancements promise to make the process faster, more cost-effective, and accessible for different uses.