What is the difference between D tooling and B tooling compression machine?

- Suase /

- SUASE NEWS

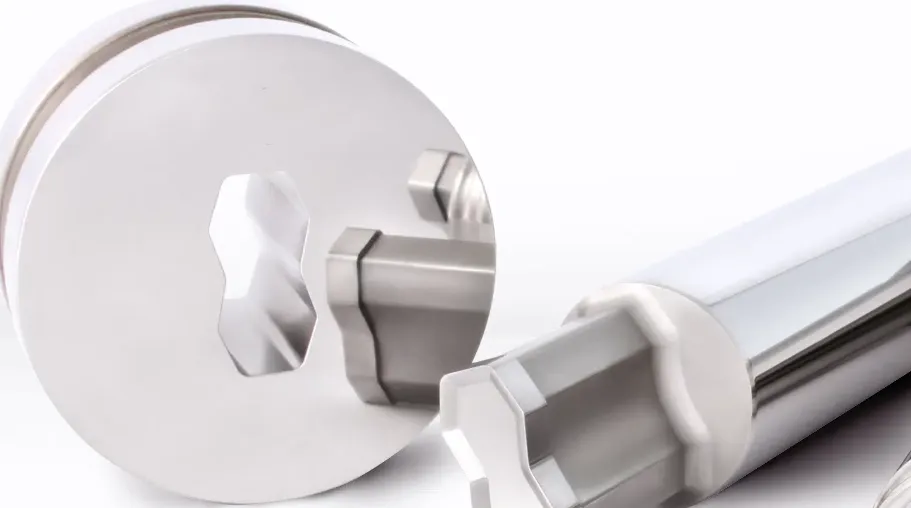

In the realm of manufacturing, the choice between D tooling and B tooling compression machines holds significant importance. Suase, a distinguished manufacturer specializing in compression tooling, recently elucidated the distinctions between these two types of equipment, highlighting their unique advantages and applications.

D tooling compression machines, also recognized as Euro or IPT type tooling, stand out with their larger punch head diameter compared to B tooling counterparts. This feature enables the production of tablets with greater diameters, making them particularly suited for formulations requiring larger-sized tablets. Furthermore, D tooling machines often boast higher tablet output rates due to their larger punch sizes.

Conversely, B tooling compression machines, also known as American type tooling, are characterized by their smaller punch head diameter. This attribute renders them ideal for manufacturing tablets with smaller diameters. B tooling machines find favor in formulations where tablet size precision is critical, such as in pediatric or geriatric medications where smaller tablet sizes are preferred for ease of consumption.

According to Suase's experts, the selection between D tooling and B tooling compression machines hinges on various factors including tablet size requirements, production capacity, and specific formulation characteristics. While D tooling machines excel in producing larger tablets at faster speeds, B tooling machines shine in precision and suitability for smaller tablet sizes.

Suase underscores that both D tooling and B tooling compression machines undergo rigorous quality control measures to ensure compliance with industry standards and regulations. Moreover, the company reaffirms its commitment to providing comprehensive support and technical assistance to pharmaceutical manufacturers in selecting the most suitable equipment for their production needs.

In conclusion, Suase's insights emphasize the importance of discerning the disparities between D tooling and B tooling compression machines in pharmaceutical tablet manufacturing. By elucidating these differences, Suase aims to empower pharmaceutical companies to make informed decisions, thereby optimizing their production processes and product quality.