When discussing manufacturing processes for producing plastic parts, two prominent methods often come to mind: compression molding and injection molding. Both techniques have their unique advantages, applications, and operational nuances. Understanding the differences between compression molds and injection molds is crucial for selecting the appropriate method for specific projects. This article delves into the intricacies of both molding processes, highlighting their distinct features, benefits, and ideal use cases.

Compression Molding

Compression mold involves placing a pre-measured amount of raw plastic material, known as a charge, into an open, heated mold cavity. The mold is then closed, and pressure is applied, causing the material to conform to the shape of the mold cavity. This process is particularly effective for producing large, intricate parts with high strength and excellent surface finish.

Compression Molding Process

- Preparation: The raw material, often in the form of a preformed slug or sheet, is prepared and measured according to the part specifications.

- Heating: The mold is preheated to the required temperature to ensure the material flows and cures properly.

- Placing the Material: The pre-measured raw material is placed into the mold cavity.

- Molding: The mold is closed, and pressure is applied, forcing the material to flow and fill the mold cavity. The combination of heat and pressure allows the material to cure and take the shape of the mold.

- Cooling and Ejection: After the material has cured, the mold is cooled, and the finished part is ejected.

Advantages of Compression Molding

- Ideal for large, complex parts with high strength requirements.

- Excellent for producing parts with uniform thickness.

- Cost-effective for medium to large production runs.

- Capable of using a wide variety of materials, including thermosets and thermoplastics.

Injection Molding

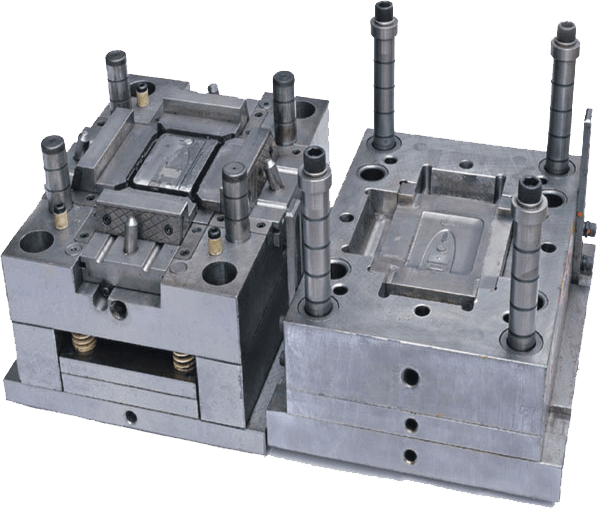

Injection mold, on the other hand, is a more automated process where plastic material is melted and injected into a mold cavity under high pressure. This method is widely used for mass-producing complex plastic parts with high precision and consistency.

Injection Molding Process

- Melting the Material: Plastic pellets are fed into a hopper and then heated in a barrel until they reach a molten state.

- Injecting the Material: The molten plastic is injected into a mold cavity through a nozzle. High pressure ensures that the material fills the entire cavity.

- Cooling: Once the mold is filled, the material is allowed to cool and solidify.

- Ejection: After cooling, the mold opens, and the finished part is ejected.

Advantages of Injection Molding

- Highly efficient for high-volume production.

- Capable of producing complex parts with intricate details and tight tolerances.

- Minimal waste due to the precise control of material flow.

- Fast cycle times, enhancing production speed and efficiency.

Key Differences Between Compression Mold and Injection Mold

Material Handling

Compression Mold: Uses pre-measured raw material placed directly into the mold cavity. The material can be in the form of a slug or sheet.

Injection Mold: Utilizes plastic pellets that are melted before being injected into the mold cavity.

Process Complexity

Compression Mold: Generally simpler with fewer automated steps, making it suitable for medium to large parts with less intricate designs.

Injection Mold: Highly automated with precise control over material flow, ideal for complex, high-precision parts.

Cycle Time

Compression Mold: Longer cycle times due to the need for material placement, heating, and cooling within the mold.

Injection Mold: Shorter cycle times, allowing for rapid production of large quantities of parts.

Part Size and Complexity

Compression Mold: Better suited for larger, thicker parts with uniform dimensions.

Injection Mold: Excellent for small to medium-sized parts with intricate details and tight tolerances.

Material Variety

Compression Mold: Can handle a wider variety of materials, including thermosets and thermoplastics.

Injection Mold: Primarily used for thermoplastics but can also process some thermosets.

Cost and Scalability

Compression Mold: More cost-effective for medium to large production runs and less complex parts.

Injection Mold: Higher initial tooling costs but highly economical for large-scale production due to its efficiency and speed.

Choosing the Right Molding Process

Selecting between compression molding and injection molding depends on several factors, including the nature of the part, production volume, material requirements, and budget constraints.

-

Compression Molding is ideal for:

- Large, durable parts requiring high strength.

- Projects where material variety is crucial.

- Medium to large production runs where cost efficiency is a priority.

-

Injection Molding is best suited for:

- High-volume production of small to medium-sized parts.

- Parts requiring intricate details and tight tolerances.

- Applications where rapid production and minimal waste are essential.

Conclusion

Understanding the fundamental differences between compression mold and injection mold is essential for optimizing production processes in the plastics industry. While compression molding offers versatility and strength for larger parts, injection molding excels in producing complex, high-precision components efficiently. By carefully considering the specific requirements of each project, manufacturers can choose the most appropriate molding technique to achieve their desired outcomes, ensuring high-quality, cost-effective production.