Let's take a look at the benefits, applications, and innovations of prepreg composite materials.

Introduction

In industries like aerospace, automotive, and beyond, the search for lightweight, strong, and durable materials is driving innovation. Prepreg composites have really taken off as a game-changing material, offering some pretty impressive properties and applications. This article looks at what prepreg composites are, what makes them so useful, where they're being used, and the latest developments that are going to have a big impact on engineering.

What exactly are prepreg composites?

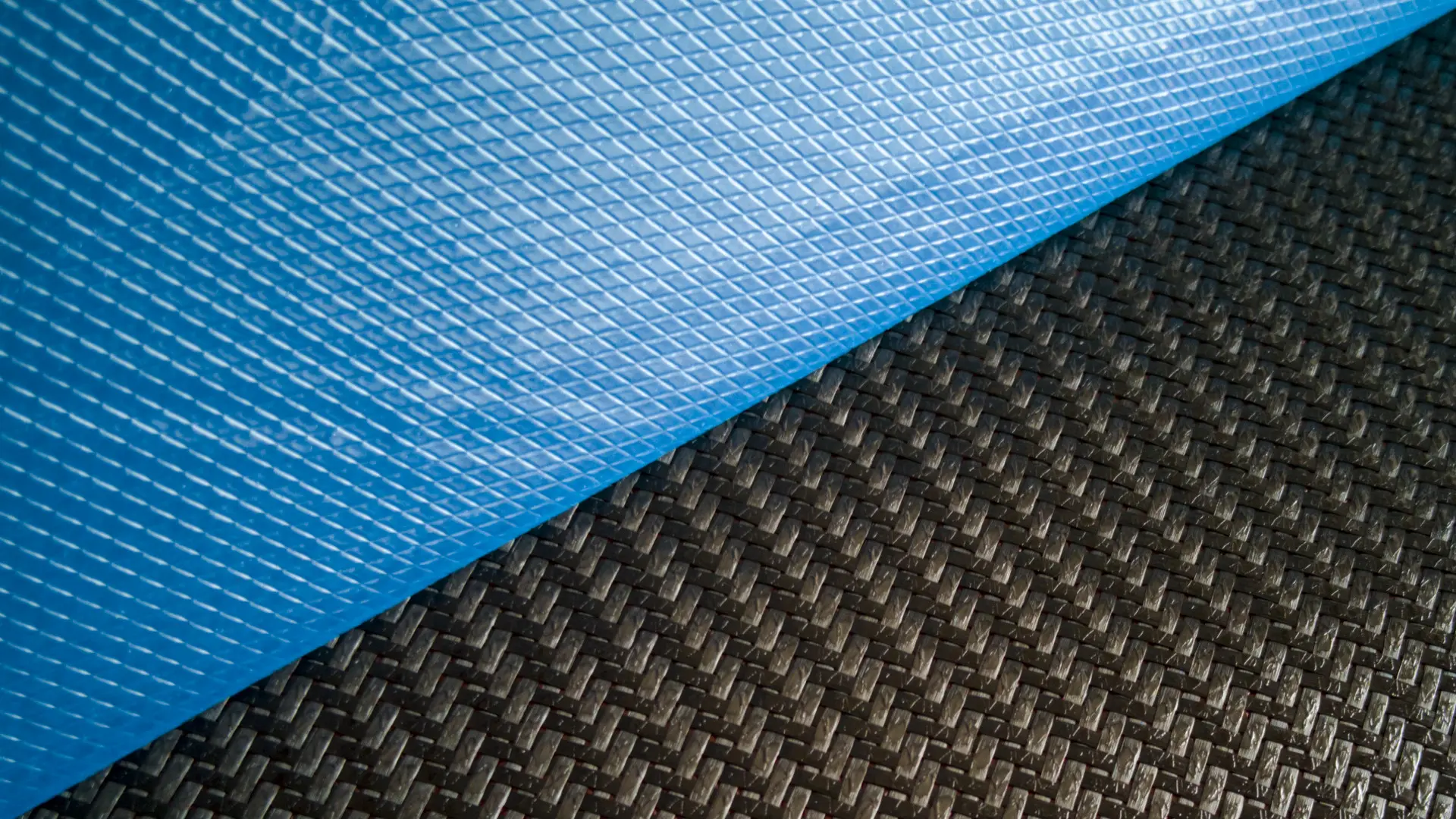

Prepreg composites are a type of advanced material made by combining reinforcement fibers (like carbon or glass fiber) with a partially cured resin matrix. They're often called "pre-impregnated composites." These materials are usually available in sheet or roll form, and they can be cut and molded into components for various applications.

What are the benefits of prepreg composites?

- It's got a high strength-to-weight ratio. Prepreg composites are a lot lighter than metals like steel or aluminum, which makes them perfect for industries where weight is a big issue.

- You can also customize the properties to suit your needs. Engineers can adjust the properties, like stiffness, flexibility, and impact resistance, by changing the type of fiber, where it's placed, the resin, and how it's cured.

- Corrosion Resistance: Unlike a lot of other metals, prepreg composites don't corrode, so they're great for harsh environments.

- They're low maintenance, too. Prepreg structures often need less upkeep because they don't rust or degrade in other ways.

Where are prepreg composites used?

Prepreg composites find widespread use across various industries:

- In the aerospace industry, prepreg composites are used in a number of ways. Aircraft structures are lighter and more fuel-efficient while still being strong and durable.

- In the automotive industry Lightweight body panels and structural components help improve fuel efficiency and crash safety.

- Sports Equipment: High-performance gear like tennis rackets, golf clubs, and bicycle frames use prepreg composites to get the best strength-to-weight ratio.

- Wind Energy: Lightweight yet strong wind turbine blades help make renewable energy more efficient and reliable.

- Construction: Reinforced prepreg composites make bridges, buildings, and other infrastructure more durable and long-lasting.

Recent Advancements in Prepreg Composites

The field of prepreg composites is moving forward with some amazing new developments:

- Automated Manufacturing: Technologies like automated tape laying and fiber placement help cut labor costs and make products more consistent.

- Nanotechnology Integration: Adding materials like carbon nanotubes and graphene makes things stronger and more conductive.

- Recyclability: The development of recyclable prepreg composites is helping to address environmental concerns and reduce waste.

- 3D Printing: New 3D printing techniques let us make complex prepreg composite structures with greater precision, opening up new possibilities.

Conclusion

Prepreg composites are leading the way in material innovation, offering unmatched benefits in weight reduction, strength, and durability. From aerospace to sports and renewable energy, these materials are transforming industries. With ongoing research and development, the future of prepreg composites is bright, promising groundbreaking applications and continued advancements.