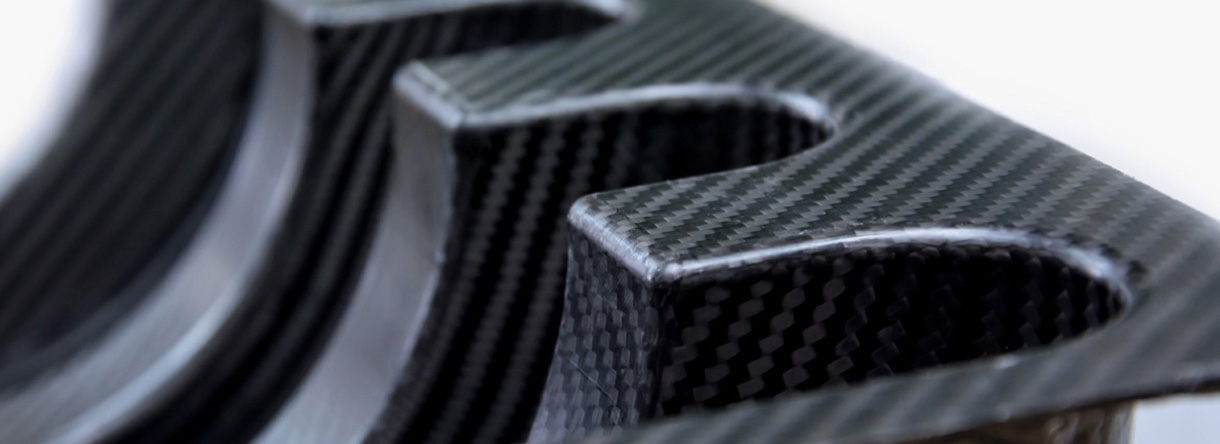

Known for its high strength-to-weight ratio, carbon fiber is widely used in a variety of industries, including aerospace, automotive and sports equipment. However, its durability and strength can make cutting and trimming carbon fiber challenging without the proper techniques and tools. Whether you're working with carbon fiber sheets, fabrics or parts, proper trimming is essential to ensure clean, precise cuts while maintaining the material's structural integrity.

Understanding Carbon Fiber and Its Cutting Challenges

Carbon fiber is made up of thin strands of carbon that are woven together to form sheets or fabrics. It is then impregnated with resin to create a strong, lightweight material. While its exceptional strength makes it a popular choice, it also presents some unique cutting challenges.

The main challenge in cutting carbon fiber is its ability to produce jagged, frayed edges if not handled properly. Carbon fiber also produces fine dust during cutting, which can be harmful if inhaled. Therefore, trimming carbon fiber requires special tools and safety precautions to achieve the best results.

Tools You Need for Trimming Carbon Fiber

The right tools are essential for ensuring a clean cut while minimizing the risk of damaging the material. Here are some common tools used for trimming carbon fiber:

1. Saw Blades

When it comes to cutting thick sheets or parts, a saw blade can be the most efficient tool. However, not all saw blades are suitable for cutting carbon fiber. The ideal saw blades for carbon fiber are those with fine-toothed edges and carbide-tipped teeth, as these are designed to handle the abrasiveness of the material.

- Circular Saw: A circular saw with a carbide-tipped blade works well for straight cuts in thicker sheets.

- Band Saw: A band saw can be used for both straight and curved cuts, making it a versatile tool for various trimming tasks.

- Table Saw: A table saw fitted with a fine-toothed blade can provide accurate straight cuts and is ideal for larger sheets of carbon fiber.

2. Utility Knife or Razor Blade

For cutting carbon fiber fabric or thin sheets, a utility knife or razor blade can provide precision and control. The sharp edge of the blade allows you to make clean cuts along marked lines, avoiding jagged edges. This tool is best for smaller or more intricate cuts, such as trimming fabric around curved parts.

3. Dremel Tool

A Dremel tool equipped with a fine cutting disc is perfect for trimming small carbon fiber parts, making it a popular choice for detailed work. The Dremel allows you to cut, grind, and polish carbon fiber with precision, especially when dealing with complex shapes.

4. Jigsaw

A jigsaw fitted with a fine-toothed blade is another versatile tool for trimming carbon fiber. It's ideal for making both straight and curved cuts. It is especially useful for cutting parts with irregular shapes, such as those found in automotive or aerospace applications.

5. Shears

Special composite shears can be used for carbon fiber fabrics and lighter weight sheets. These shears are designed to cut through the carbon fiber layers without fraying or delaminating, providing a clean cut with minimal effort.

How to Trim Carbon Fiber Safely

Trimming carbon fiber can create harmful dust and particles that can be hazardous to your health. To ensure a safe working environment, always wear appropriate protective equipment and follow these safety tips:

1. Wear Protective Gear

Always wear safety glasses, a dust mask, and gloves when cutting carbon fiber. The fine dust produced during cutting can irritate your eyes, lungs, and skin, so protective equipment is essential. In addition, wearing long sleeves and pants will help protect your skin from the sharp edges of carbon fiber pieces.

2. Work in a Well-Ventilated Area

Because carbon fiber dust can be harmful if inhaled, make sure you work in a well-ventilated area. Use a dust extraction system or a vacuum with a HEPA filter to capture the dust and reduce its concentration in the air.

3. Use a Cutting Mat or Surface

Place a protective cutting mat or surface under the material to avoid damaging the workbench or creating unnecessary wear on your tools. This will also provide additional stability during the cutting process.

4. Avoid Excessive Heat

When cutting carbon fiber, avoid generating excessive heat, as this can cause the resin to melt, potentially compromising the material. Use sharp blades and cutting tools to ensure clean, efficient cuts without generating too much friction or heat.

Step-by-Step Guide: How to Trim Carbon Fiber

Step 1: Measure and Mark

Before starting the cutting process, accurately measure and mark the area to be trimmed. Use a ruler or tape measure and a permanent marker or pencil to outline the cutting lines. Make sure the lines are straight and accurate to avoid wasting material.

Step 2: Secure the Material

Use clamps or a vice to hold the carbon fiber material in place while cutting. This will prevent the material from shifting during the cutting process and ensure more accurate cuts. If you're cutting carbon fiber fabric, use fabric weights to keep the material stable.

Step 3: Choose the Right Tool

Choose the appropriate tool based on the thickness and type of carbon fiber material you're cutting. For thicker sheets, use a saw with a carbide-tipped blade. For lighter fabrics or thinner sheets, use a utility knife or scissors. Make sure the tool you use is sharp and clean to avoid damaging the material.

Step 4: Start Cutting

Begin cutting slowly and evenly along the marked lines. For saws and jigsaws, use slow speeds to avoid excessive heat buildup. For razor blades or utility knives, apply even pressure to achieve a clean cut without fraying the edges.

Step 5: Finish the Edges

After cutting the carbon fiber, use sandpaper or a file to smooth any rough or sharp edges. Be sure to use fine sandpaper (e.g., 400 grit) to avoid damaging the material. If you're working with carbon fiber fabric, you can also trim the edges with fabric scissors for a cleaner finish.

Best Practices for Achieving Clean and Precise Cuts

- Use Sharp Tools: Dull tools can cause jagged edges and splinters. Make sure your blades or cutting discs are sharp to achieve clean, precise cuts.

- Cut Slowly and Steadily: Rushing the cutting process can lead to uneven or rough edges. Take your time to ensure precision.

- Trim in Small Sections: If the carbon fiber part is large or complex, break the cutting process down into smaller sections to maintain control and reduce the risk of mistakes.

Conclusion

Trimming carbon fiber is a precise process that requires the right tools, techniques, and safety precautions. Whether you're cutting sheets, fabrics, or parts, using the correct method will ensure clean cuts and protect the integrity of the material. By following the guidelines and using the proper tools, you can achieve high-quality results in your carbon fiber projects, whether they’re for aerospace, automotive, or sports applications.